Manufacturing precision injection molded components and mold tooling with tolerances of 0.001 mm. Serving the automotive, electronics, consumer electronics, industrial and medical markets, with manufacturing facilities in China and specializing in:

- Tooling Design and Manufacturing

- Precision Injection and Insert Molding

- Reel-to-Reel Insert Molding

- Two-Shot Molding

- Precision Progressive Die Stamping

Utilizing engineering grade materials ranging from nylon and polycarbonate to challenging high performance resins such as PPS, PEEK and LCP. Quality systems include ISO9001:2008, ISO/TS16949:2009 and ISO14001. Process controls in place include APQP, PPAP, FMEA, MSA and SPC.

Manufacturing Capabilities

- Tooling

- Ram/Sinker EDM

- Wire EDM

- High Speed CNC

- Grinding/Milling

- Injection and Insert Molding

- Horizontal and Vertical Machines to 320 Tons

- Automated Insert Molding

- Engineering Grade Materials

- Reel-to-Reel Molding

- Multi-Cavity With or Without Hot Runner System

- One or Two Row Metal Strip Feeding, In and Out

- Post Cutting and Forming

- Two-Shot Molding

- Two-Shot Molding

-

250 Ton Presses

-

Accuracy: 0.0008" (0.02 mm)

-

Max Shot Size: 204 g

-

Clamping Force: 168T to 368T

-

Two Independent Ratio Flow Control Systems With Flow Position Feedback

-

- Progressive Die Stamping

- Machines to 110 Tons

- Stamping to 0.003" (0.076 mm)

- Copper, Phosphor Bronze, BeCu, SPCC, Stainless Steel and Other Materials

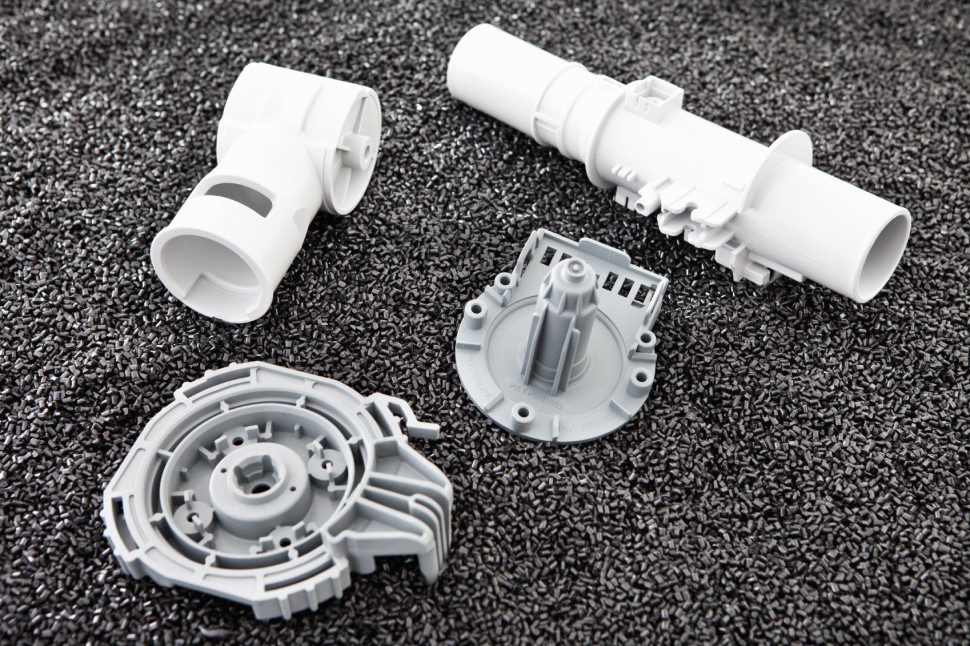

Precision Injection Molding

Custom Precision Components

Connector Assembly

Housing - Two Shot

Receptacle

SIM Card

Precision Stamping

Precision Stamping